Reducing Embodied Carbon in Buildings: The Role of Consequential Life Cycle Assessment

The built environment is responsible for an astounding 40% of annual global CO₂ emissions, with 27% attributed to building operations and another 23% to the embodied carbon in construction materials like concrete, steel, and aluminum. To address this challenge, reducing embodied carbon is essential to achieving climate goals. A Consequential Life Cycle Assessment (CLCA) is a critical tool for understanding and mitigating the environmental impacts of material and design choices in building construction.

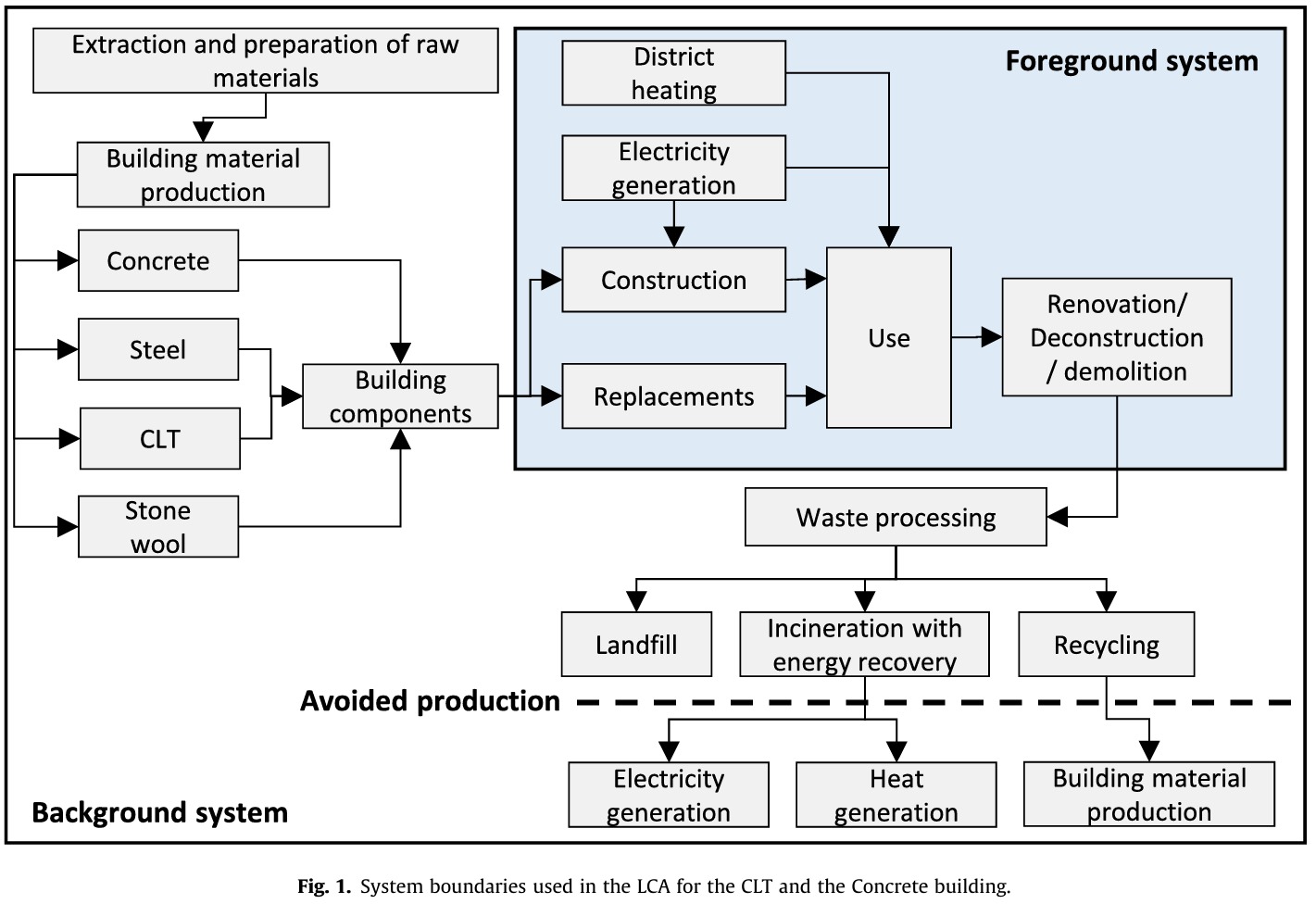

Unlike Attributional Life Cycle Assessment (ALCA), which evaluates the share of global environmental burdens attributed to a product, CLCA examines how these burdens change in response to decisions. By focusing on the broader effects of material selection and design strategies, CLCA provides the insights needed to make transformative, low-carbon choices in the built environment.

Embodied Carbon in Construction: A Target for Change

According to Architecture 2030, three materials—concrete, steel, and aluminum—contribute significantly to global CO₂ emissions:

- Concrete: Accounts for 11% of global emissions due to its widespread use and high energy demand during production.

- Steel: Represents 10%, primarily from its role in structural systems.

- Aluminum: Contributes 2%, often used in facades and specialized applications.

Together, these materials present an enormous opportunity for embodied carbon reduction through better design, material choices, and policy interventions.

Leveraging Consequential LCA for Low-Embodied Carbon Design

CLCA is a dynamic tool that allows stakeholders to predict how design and material decisions impact emissions across a building’s lifecycle. Below are key areas where CLCA can drive meaningful change:

1. Optimizing Material Selection

CLCA enables designers to evaluate and choose lower-carbon alternatives:

- Low-Carbon Concrete: Use supplementary cementitious materials (SCMs) like fly ash or slag.

- Recycled Metals: Prioritize recycled steel and aluminum to lower energy inputs.

- Bio-Based Alternatives: Materials like cross-laminated timber (CLT) provide renewable options for structural applications.

2. Encouraging Circular Design Principles

Circularity complements CLCA by extending the life of materials and reducing waste:

- Material Reuse: Deconstruct buildings for material recovery rather than demolition.

- Design for Disassembly: Specify modular systems and components that can be repurposed or recycled.

3. Policy and Regulatory Interventions

CLCA supports policymakers in creating frameworks that promote low-carbon construction:

- Carbon Pricing: Internalize the environmental costs of high-carbon materials.

- Performance Standards: Set embodied carbon benchmarks for public and private projects.

- Procurement Policies: Mandate the use of sustainable materials in government contracts.

4. Integration with Advanced Design Tools and Computational Workflows

To achieve low-carbon buildings, integrating CLCA into advanced design tools is critical. This includes:

- Parametric Design for Optimization:

Tools like Grasshopper or Dynamo, integrated with BIM platforms like Revit, allow for rapid iteration of material and structural layouts. By connecting these tools to CLCA datasets, designers can optimize embodied carbon in real time while maintaining structural performance. - Material Databases for Precision:

Integrating EPD databases like One Click LCA or Athena Impact Estimator provides region-specific data for accurate carbon assessments, ensuring material choices align with sustainability goals. - Whole-Building Analysis:

Advanced workflows enable whole-building CLCA integration, allowing teams to identify and mitigate carbon hotspots across structural, envelope, and interior systems. - Predictive Analytics:

Machine learning models can predict the embodied carbon of a building based on typology, size, and location, providing early benchmarks and enabling smarter design decisions. - Lifecycle Balancing:

Combining operational energy simulations with embodied carbon assessments ensures that trade-offs (e.g., thicker insulation vs. material intensity) are optimized for lifecycle performance. - Automated Compliance Checks:

As regulatory frameworks evolve, CLCA tools can automate compliance with embodied carbon standards, streamlining documentation for certifications like LEED or BREEAM.

5. Empowering Collaboration Across Stakeholders

CLCA fosters collaboration among architects, engineers, contractors, and policymakers by providing a unified framework for decision-making. Shared platforms ensure alignment in goals, reducing miscommunication and enabling more efficient project delivery.

Benefits of Adopting Consequential LCA

- Environmental Impact

Reduce global emissions by lowering the embodied carbon of construction materials. - Economic Efficiency

Optimize material use and operational performance, reducing costs over the building’s lifecycle. - Regulatory Preparedness

Stay ahead of emerging embodied carbon standards and gain recognition for sustainability leadership. - Enhanced Market Positioning

Demonstrate commitment to climate action, attracting environmentally conscious clients and stakeholders.

Consequential Life Cycle Assessment is a cornerstone of sustainable building design, providing the data-driven insights necessary to reduce embodied carbon and mitigate climate change. By integrating CLCA into design workflows, material selection processes, and policy frameworks, the construction industry can transition to a low-carbon future.